Introduction

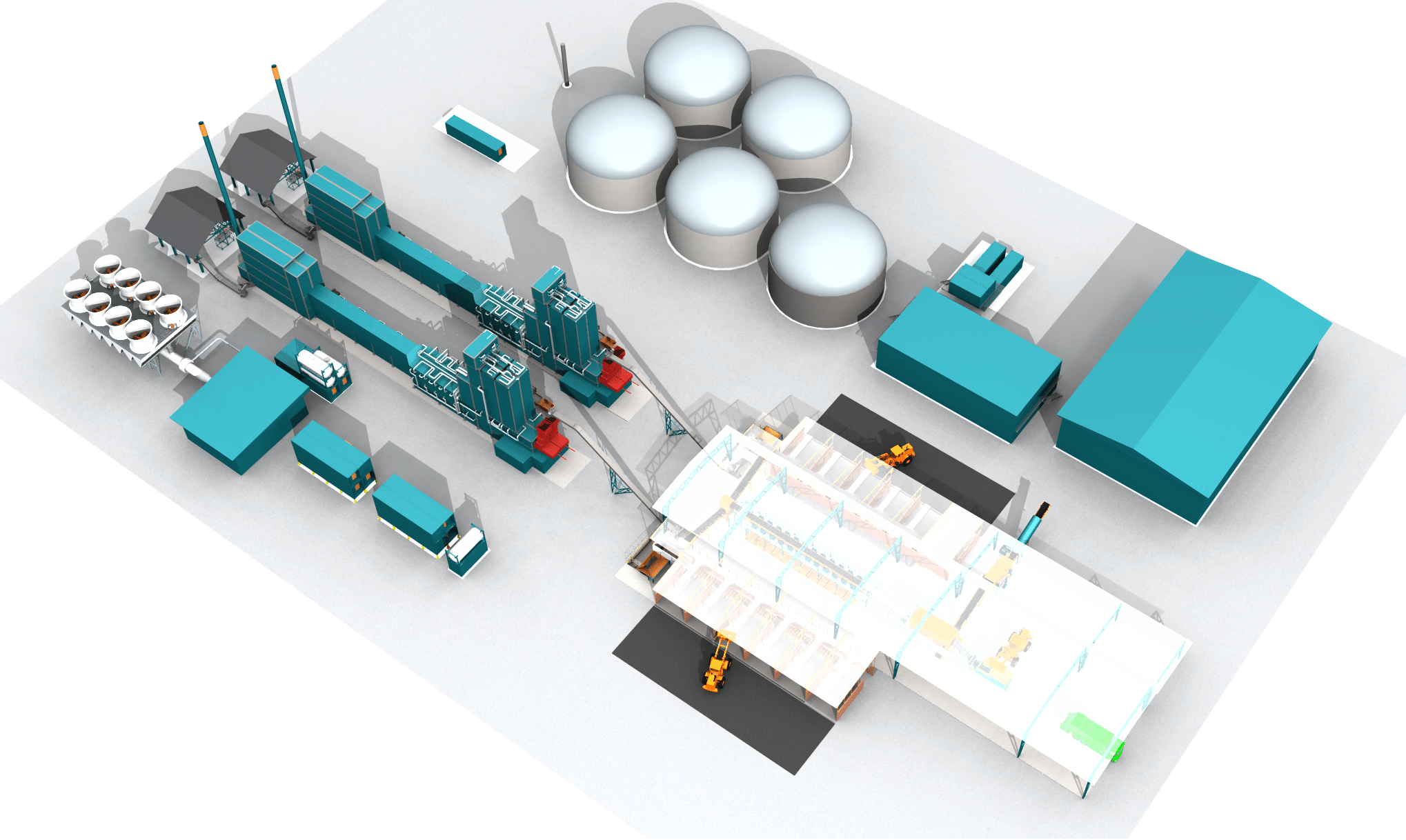

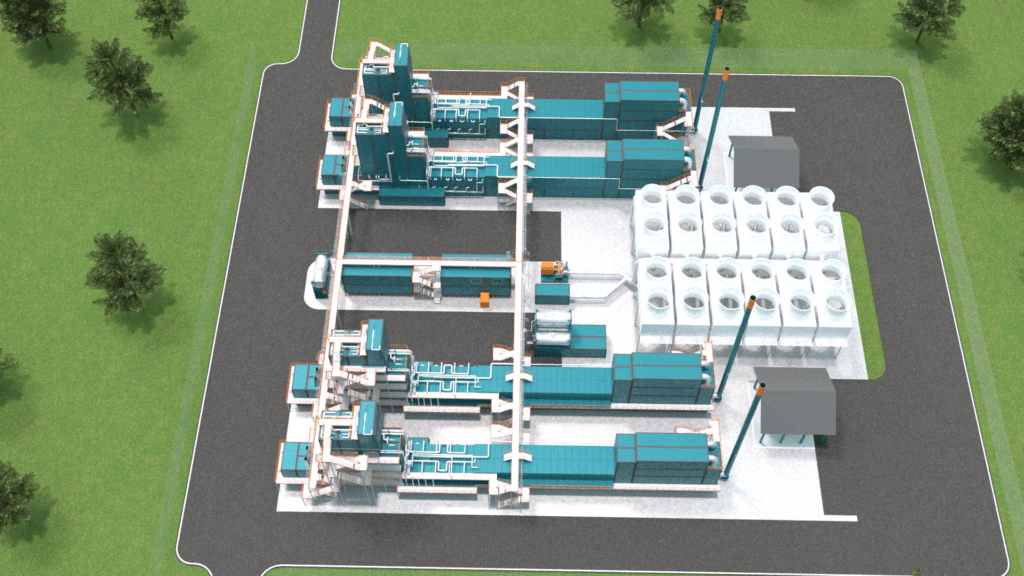

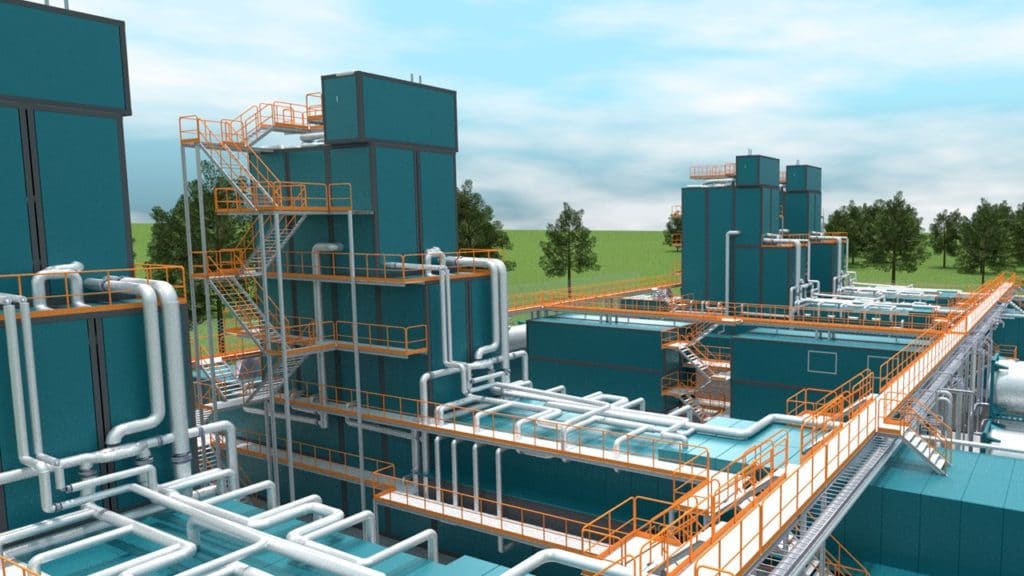

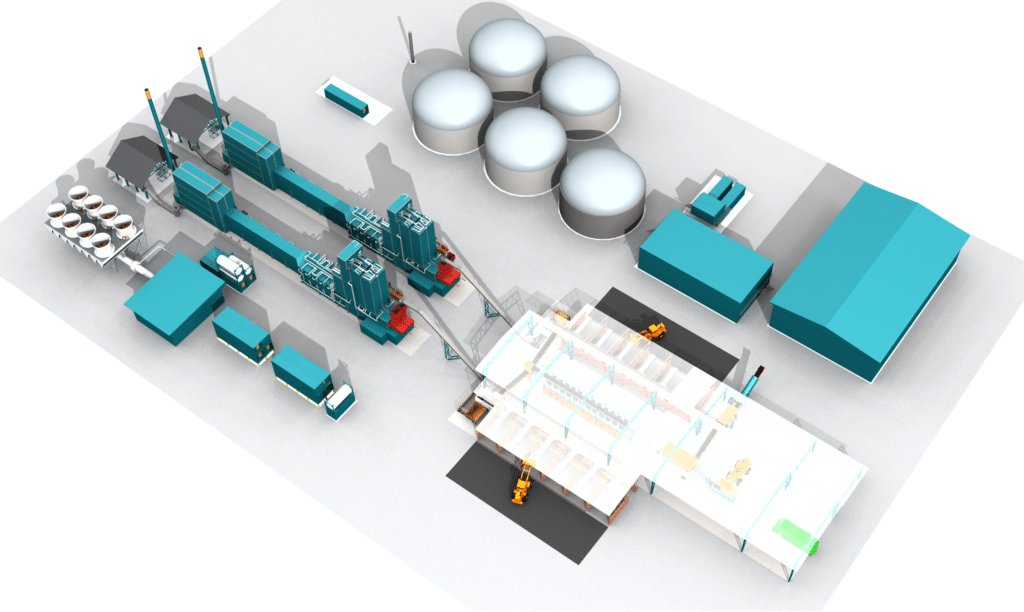

The wasteWOIMA® waste-to-energy power plant is one of the most efficient, versatile, flexible and adaptable power plants in the world. It offers several benefits and advantages to all stakeholders, including the environment. Investors, waste management companies, power generation entities and local population alike are the beneficiaries of increased energy generation, reduced waste-landfilling and cleaner environment.

The wasteWOIMA® power plant is the “heart and soul” of the WOIMA Ecosystem that embraces the opportunities created by society’s different waste streams. It ensures that all the waste can be recycled as raw material, transformed into energy or otherwise mitigated. The usable waste streams include municipal solid waste (MSW), industrial, commercial and institutional waste (ICI), agricultural waste (AW), construction and demolition waste (CDW), as well as different types of toxic waste including hospital waste.

The flexible nature of the wasteWOIMA® power plant can be divided into three categories.

1. Design-based flexibility

-

- The plant scales up (and down) in 15MW fuel power intervals ensuring that the right-size power plant is always available without the need to design it to order (Scalability)

- The plant comprises of modules that are designed to fit into standard sea container size enabling fast and easy transportation to practically any destination (Transportability)

- The prefabricated modules can be erected much faster than building a traditional power plant, and using simple tools (Constructability)

- The modular design enables the plant to be erected and dismantled without damaging the modules thus making it possible to relocate the power plant (Movability)

- The modular structure ensures good access, not restricted by an enclosing building, to all maintenance points and also enables exchanging broken or worn-out modules completely (Maintainability)

- Our continuous R&D work improves the productivity and lengthens the lifespan of the plant, while reducing the OPEX and adjusting to new regulations (Upgradeability)

- The plant design enables the incineration of several different types of waste fuels with wide calorific value, moisture and toxicity variance (Fuel flexibility)

- The plant can be delivered to any location, where sufficient fuel feed is available and power demand exists; ambient conditions pose no threat to the integrity or operation of the plant (Location suitability)

- The plant contains common and auxiliary equipment and materials that has been designed with localization in mind (Localization-readiness)

- The plant design can be based on either EN or ASME standards based on customer preference (Design-bases flexibility)

2. Operational flexibility

-

- The plant can generate thermal energy (steam, heating or cooling) and electricity, and switch between these flexibly over time (Output flexibility)

- The plant’s power output adapts automatically to changes in the ambient conditions, such as temperature and humidity, as well as changes in the customers’ ability to accept the generated power (Output adaptability)

- The plant fulfils even the strictest water, soil and air emission regulations provided it is operated according to prudent industry standards; lower requirements are met by simply reducing the chemical consumption (Emission adaptability)

- The plant’s flue gas treatment system can utilize several different chemicals in rendering the flue gases inert (Chemical flexibility)

- The plant has high level of automation, but it can also be run manually employing dozens of people, and significantly more at the adjoining waste pre-sorting facility (CAPEX/OPEX substitution)

- The base load power plant supports increasing intermittent power generation and the optional battery storage system absorbs the load fluctuations (Hybrid energy productivity)

3. Business model flexibility

-

- The fast project lead-time, continuously improved standardized design, high-quality module pre-fabrication and short construction time on site de-risk the project almost completely (Risk manageability)

- WOIMA has all the tools and processes in place to support the project developers in their work; standardized bankable solutions simplify and speed up the project development process (Project development support)

- The medium-scale power plants support decentralization of the waste management and power generation activities close to where the waste is being generated (Decentralization potential)

- The plant generates power and cash flow for all future WOIMA Ecosystem solutions offering the owner/operator new business opportunities with different waste streams not necessarily suited for incineration (Business expandability)

- The medium-scale power plants are easy to refinance; geographically distributed power plants mitigate the portfolio risks (Refinancing potential)

- The existence of the power plant creates new job, training and business opportunities both upstream and downstream in the areas of waste logistics and utilization of recycled raw materials and generated energy (Social perspective)

Combined the above-mentioned flexibilities create a unique and transcending business opportunity that benefit all stakeholders simultaneously.

Follow our blog series “22 levels of wasteWOIMA® flexibility” to find out more about how these flexibilities can help You realize Your waste-to-value project.

Download wasteWOIMA® Brochure

Find out more about wasteWOIMA technical solutions

Check Your Waste Characteristics

Contact Us

WOIMA Corporation is a Finnish supplier of best-in-class waste-to-value products, projects and services worldwide. We have developed solutions that enable us, and the customer, to transform and recycle virtually any waste stream into raw materials and energy. At WOIMA we combine Finnish engineering know-how in waste management with power generation design expertise. These solutions are used in Finland every day. They support the circular economy ideology and ensure that less than 1% of Finland’s waste ends up in landfills.

Our mission is to improve quality of life both locally and globally, as well as empower people to utilize waste as a commodity. Our decades of international project management experience ensure an on-time, in-budget and high-quality WOIMA solution delivery across the globe.