WOIMA Ecosystem Solution

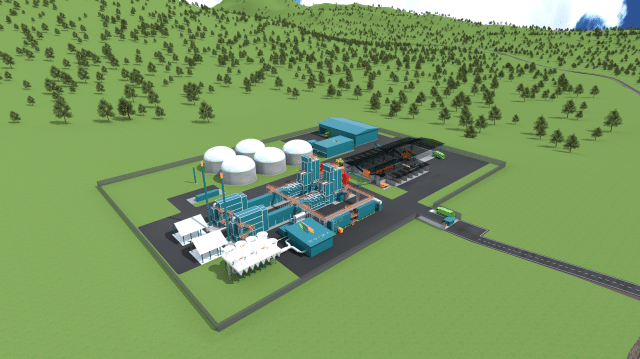

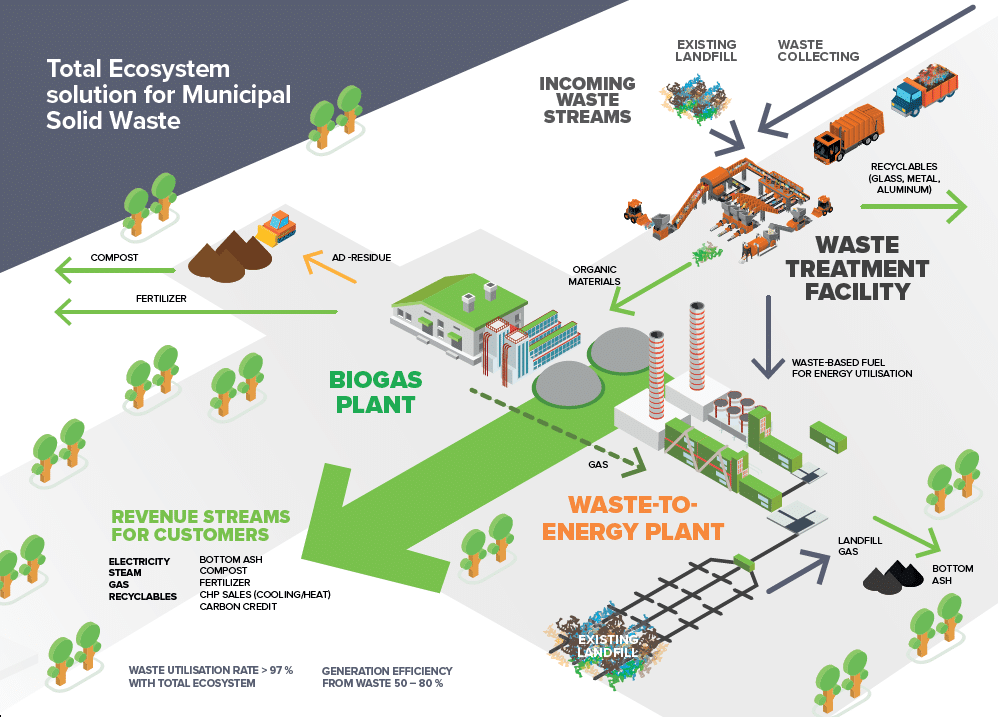

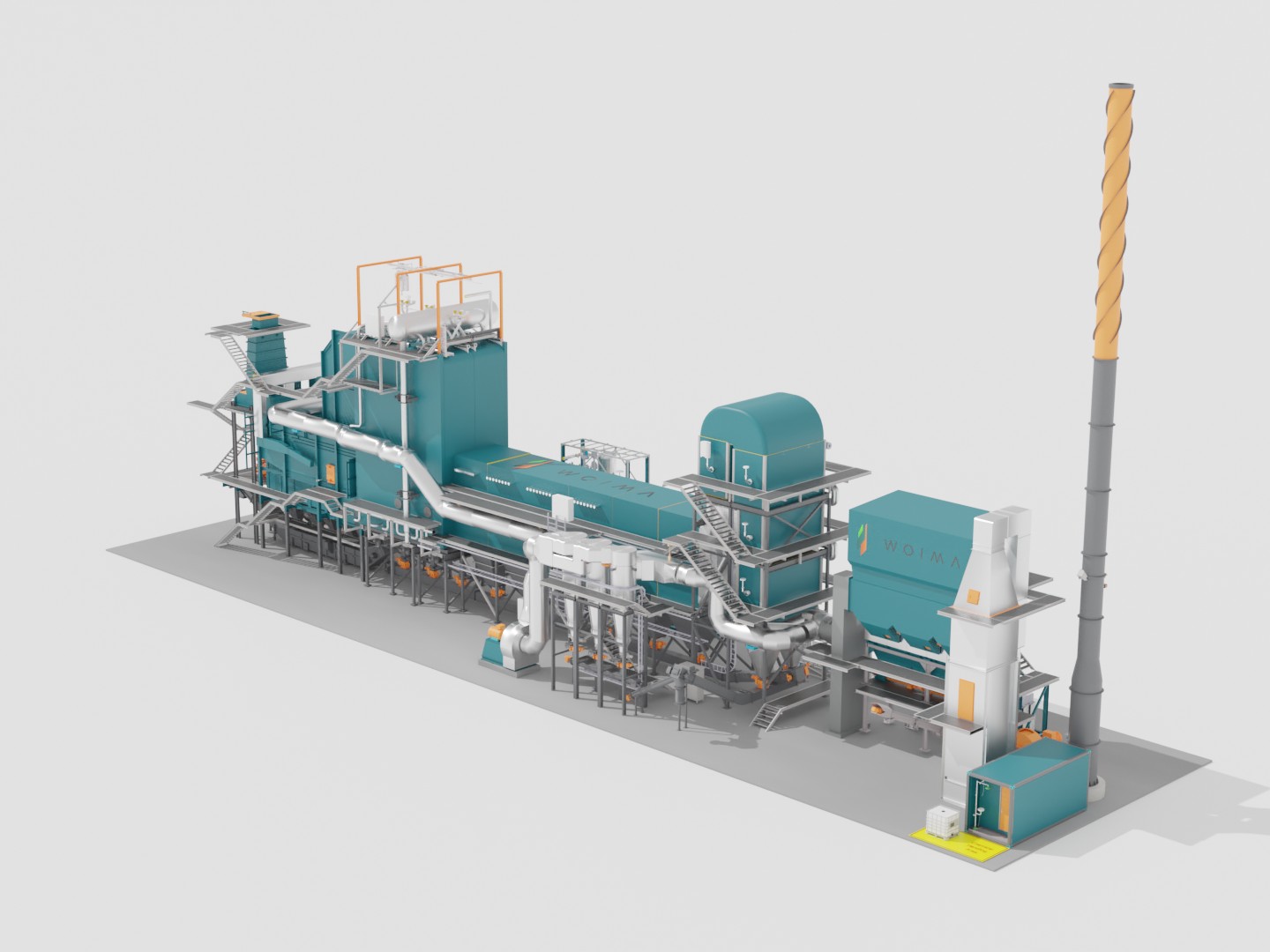

The WOIMA Ecosystem combines different waste-to-value and waste-to-energy (WtE) technologies to extract maximum customer value out of different waste streams, while reducing the unusable waste quantity to a bare minimum. Key pieces in the ecosystem are the waste pre-sorting, waste recycling or waste-to-fuel solutions, as well as waste-to-energy solutions, such as biogas production, waste incineration or gasification and pyrolysis.

The WOIMA Ecosystem accepts all the waste streams, solid and liquid, that societies generate; municipal, industrial and commercial waste, wastewater sludge and animal waste, to mention a few. Each waste stream has its own dedicated technical solution that generates either end-products, raw material for other solutions or energy. Internal ecosystem synergies ensure that one plus one equals more than two.

Waste pre-sorting prepares the waste stream for the technical solutions to follow by removing unwanted particles, segregating the waste and crushing it to suitable particle size. It also supports recycling to replace virgin raw materials. Energy, such as electricity or thermal power, is generated through incineration or gasification. Traffic fuel, also usable for cooking, heating or electricity generation, is produced in anaerobic digestion of the biodegradable material or through pyrolysis of the plastic and rubber materials. The residual matter from incineration fits brick manufacturing or cement industry’s needs, whereas the residual biomass from biogas production works perfectly as fertilizer. Any excess biodegradable matter is suitable for compost production. In this manner, over 95% of the original waste quantity is recycled either as raw material or energy.

The correct ecosystem components are selected based on the available waste fractions and demand for different energy commodities. Several different methods can be applied to the same waste stream depending on customer preference and local conditions.

The modular and pre-fabricated structure of the WOIMA Ecosystem enables the continuous development of the Ecosystem by adding new solutions, quickly over time. And if requirements change, the Ecosystem can be dismantled and relocated fast and cost-efficiently leaving only the concrete base slab behind.

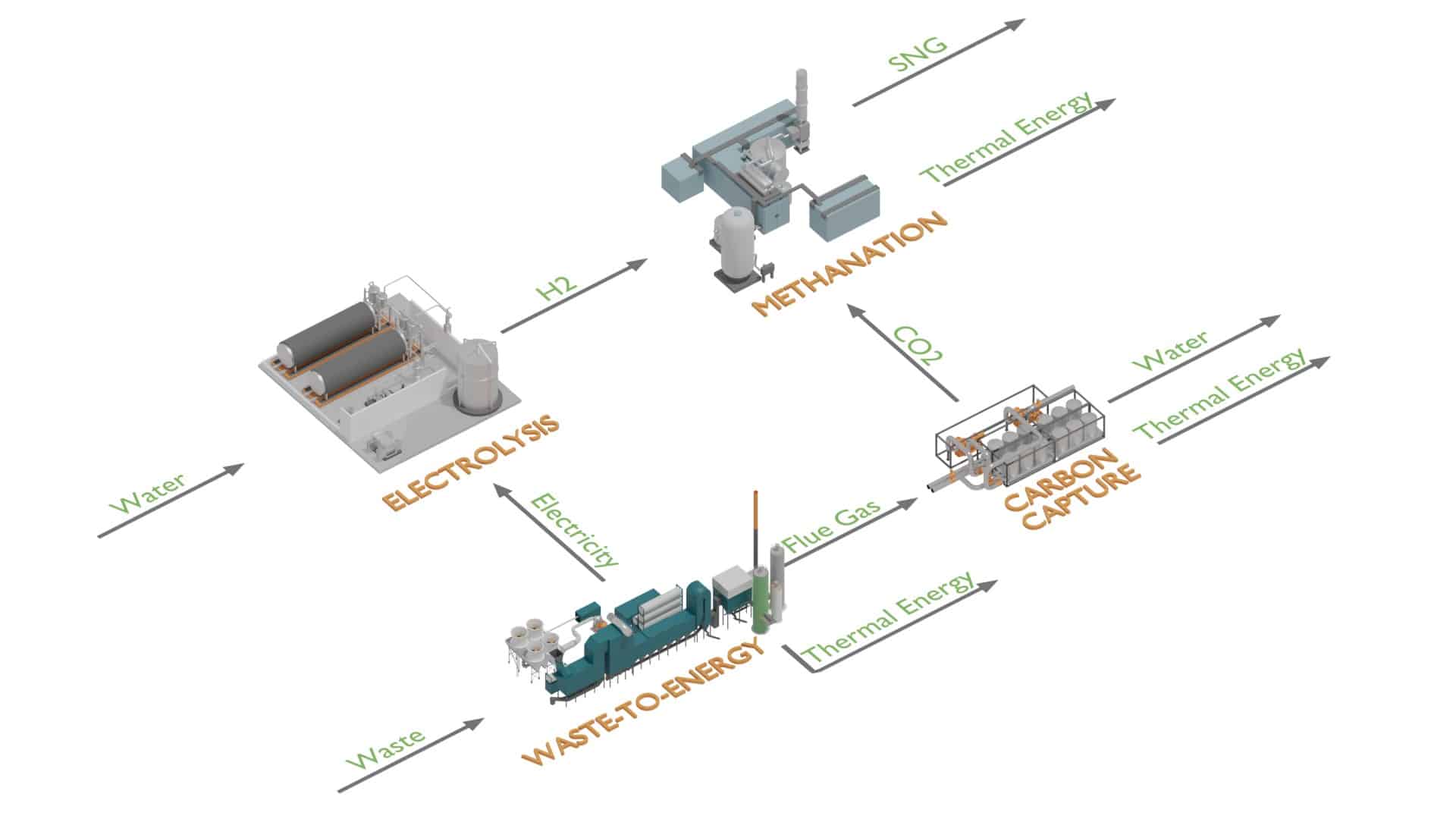

Hydrogen Production and CO2 Utilization within the WOIMA Ecosystem

The WOIMA Ecosystem also incorporates a hydrogen value chain that utilizes CO2 to further enhance its sustainability and efficiency. This addition can be conceptualized as follows: This innovative integration aligns seamlessly with the ecosystem’s core objectives of maximizing value from waste streams and minimizing waste footprint. Here’s how the hydrogen value chain fits into the WOIMA Ecosystem:

- Hydrogen Production: Utilizing waste-derived syngas (a product of gasification and pyrolysis) or biogas, the WOIMA ecosystem generates hydrogen through processes such as steam methane reforming (SMR) or gasification. This not only provides a clean energy carrier but also elevates the waste-to-value proposition.

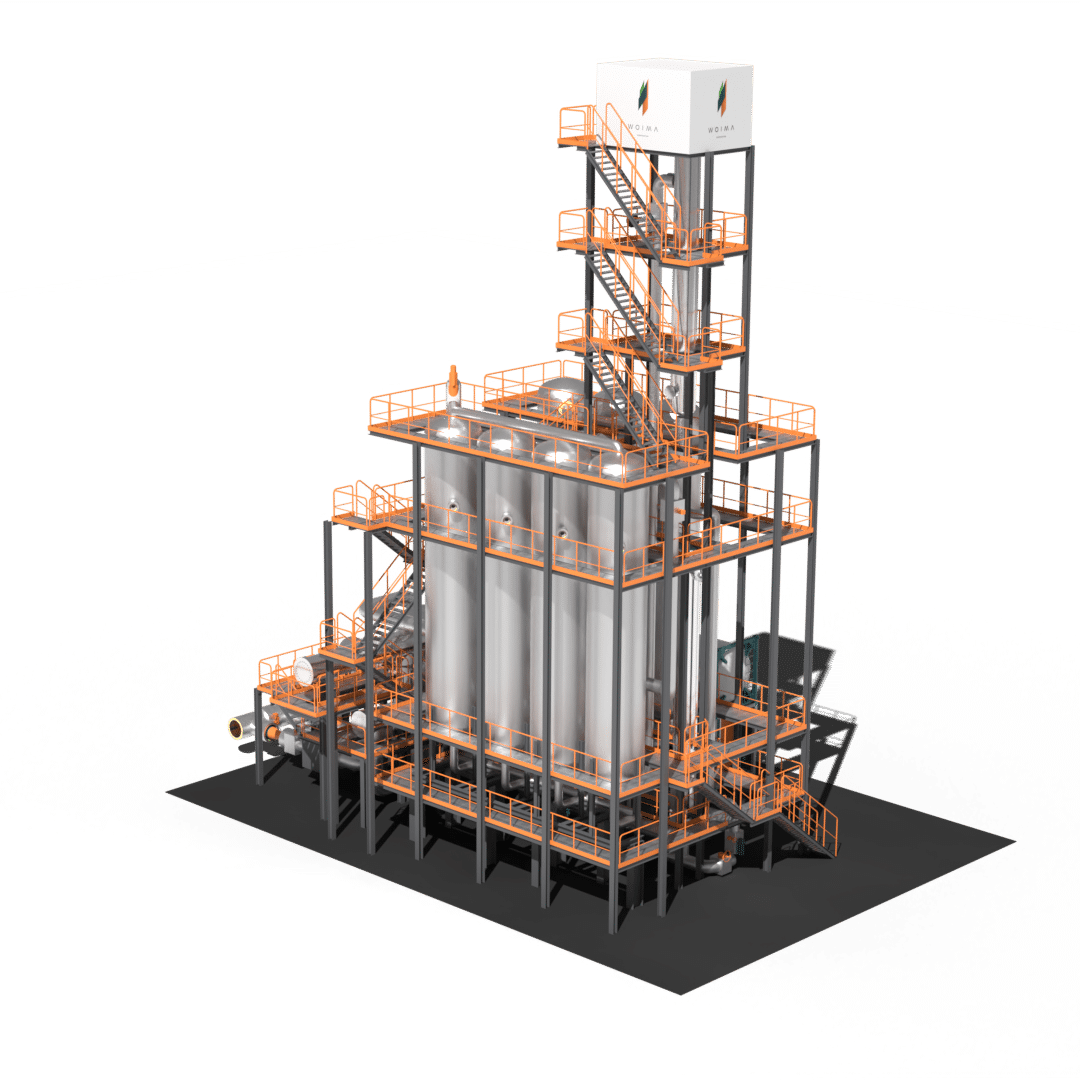

- Carbon Capture and Utilization (CCU): Concurrently, CO2 emissions from waste processing and energy production activities within the ecosystem are captured. This captured CO2 then serves as a feedstock for further valorization processes, such as in the production of synthetic fuels, chemicals, or even enhanced biogas production through methanation, where CO2 and hydrogen are converted into methane.

- Integration with Waste-to-Energy and Waste-to-Value Solutions: The hydrogen value chain enhances existing WtE and waste-to-value solutions by providing a versatile energy carrier that can be used for electricity generation, heating, or as a clean fuel for transportation. Furthermore, integrating hydrogen production can improve the overall energy efficiency of the WOIMA ecosystem and reduce reliance on fossil fuels.

- Synergy and Circular Economy Enhancement: The addition of the hydrogen value chain fosters greater internal synergies. By utilizing CO2, a byproduct of waste-to-energy processes, the ecosystem not only reduces its carbon footprint but also contributes to a circular economy. This approach ensures that waste materials are utilized to their fullest potential, generating economic value while mitigating environmental impact.

- Modularity and Scalability: The hydrogen value chain component is designed to be modular and scalable, consistent with the WOIMA Ecosystem’s architecture. This allows for easy integration into existing setups and facilitates future expansions or modifications to accommodate evolving waste management and energy production needs.

- Environmental and Economic Benefits: Incorporating the hydrogen value chain enhances the WOIMA Ecosystem’s environmental benefits by reducing greenhouse gas emissions and promoting renewable energy use. Economically, it opens up new revenue streams through the production of hydrogen and valorized CO2 products, making the ecosystem even more viable and attractive to stakeholders.

The integration of a hydrogen value chain utilizing CO2 into the WOIMA Ecosystem represents a forward-thinking approach to waste management and renewable energy production. It aligns with global sustainability goals by reducing emissions, promoting circular economy principles, and providing a scalable, efficient solution to waste management and power generation challenges.